I. Sampling Inspection Upon Arrival

This process is conducted after the insulators arrive at the warehouse or construction site. The purchaser, constructor, and supervisor jointly participate in sampling inspections according to sampling standards to evaluate the quality of the entire batch.

Visual Inspection

Method: Randomly select a certain number of insulators from the batch (sampling ratio as per standards or contract) for visual inspection by examiners using magnifying glasses if necessary.

Content:

Glass Shell: Check for cracks, bubbles, impurities, scratches, or edge chips. The glass surface should be smooth with a uniform tempered layer.

Metal Fittings: Inspect the cap and pin for rust, burrs, uneven galvanization, cracks, or deformation.

Cement Filling: Ensure the cement is fully filled, without cracks or looseness.

Locking Pin: Check the type and material of the locking pin (e.g., R-pin, W-pin) for correctness, deformation, or rust. Test assembly to ensure smooth insertion, removal, and effective locking.

Marking: Verify that the markings on each insulator (manufacturer's trademark, year of production, rated mechanical load, etc.) are clear, durable, and accurate.

Dimensional and Deviation Check

Method: Use calipers, micrometers, height gauges, and other measuring tools.

Content: Measure key dimensions such as total height, shed diameter, and creepage distance to ensure they comply with the tolerance ranges specified in the standard drawings.

Temperature Cycle Test

Purpose: To evaluate the insulator and its cemented parts' ability to withstand rapid temperature changes and assess thermal stability.

Method: Cycle the sample between hot (e.g., +70°C) and cold (e.g., -30°C) water baths several times. Then, perform a mechanical load test in hot water or measure its residual strength to check for damage or strength reduction.

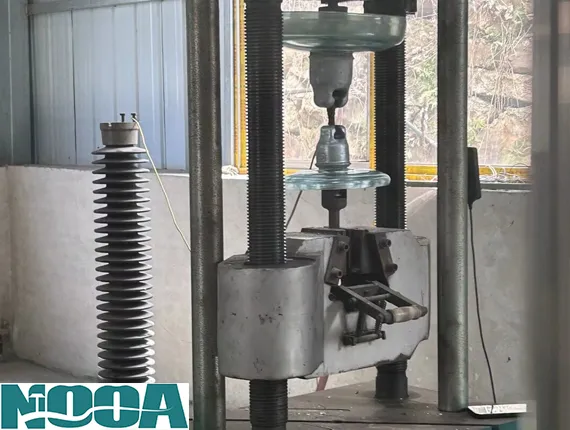

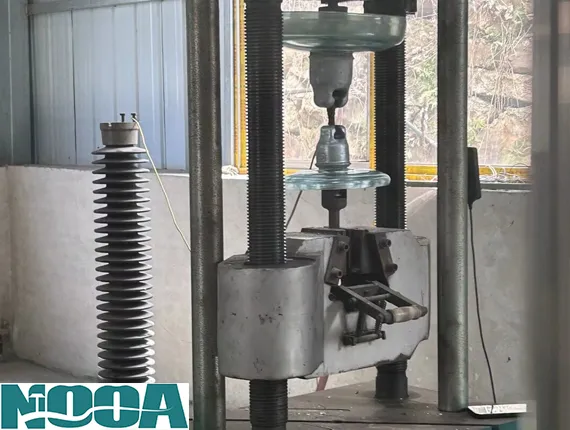

Mechanical Failing Load Test

Purpose: To verify that the mechanical strength of the insulator meets the rated value.

Method: Apply gradually increasing tensile or bending load to the sample using a dedicated testing machine until failure. Record the failing load value, which should not be less than its Specified Mechanical Load (SML).

Electro-Mechanical Failing Load Test

Purpose: To test the comprehensive performance under simulated operating conditions by applying high voltage simultaneously with mechanical load.

Method: Apply a specified high voltage (usually power frequency AC voltage) to the sample while gradually increasing the mechanical tensile load until failure. No puncture or flashover should occur during the test.

Puncture Withstand Test

Purpose: To examine the intrinsic electrical insulation strength of the insulator's dielectric material, ensuring it does not break down under high voltage.

Method: Short-circuit the metal parts (cap and pin) of the insulator and immerse it in insulating oil. Apply a specified high voltage between the short-circuited metal parts and an external electrode for a duration without causing puncture.

Thermal Shock Test

Purpose: Specifically for toughened glass insulators, to check the quality of the tempering. Poorly tempered glass will shatter completely under thermal shock.

Method: Heat the sample in a furnace to a specific temperature, then quickly immerse it in cold water. Observe if the glass shell breaks (properly toughened glass should remain intact).

Zinc Coating Test

Purpose: To check the quality and thickness of the zinc coating on metal fittings, ensuring corrosion resistance.

Method: Measure the coating thickness using a magnetic thickness gauge or perform a copper sulfate immersion test to check uniformity.