Residual Mechanical Strength is a key indicator used to evaluate how much load a glass insulator can still withstand after it has been damaged. It is directly related to the safe and reliable operation of transmission lines when local damage occurs to an insulator. Simply put, the higher the residual mechanical strength, the less likely a self-exploded or mechanically damaged insulator is to cause a full string failure or conductor drop.

Basic Concept

Residual mechanical strength refers to the tensile or bending load capacity that an insulator can still sustain after partial mechanical damage (such as self-explosion of a disc glass insulator or local fragmentation). It is usually expressed as a percentage of the original rated mechanical load or ultimate breaking load.

For glass and porcelain insulators used on overhead transmission lines, national and international standards clearly define test methods and minimum requirements for “residual mechanical strength after mechanical damage,” which are used to assess the safety margin of insulators under damaged operating conditions.

Relationship with Glass Insulators

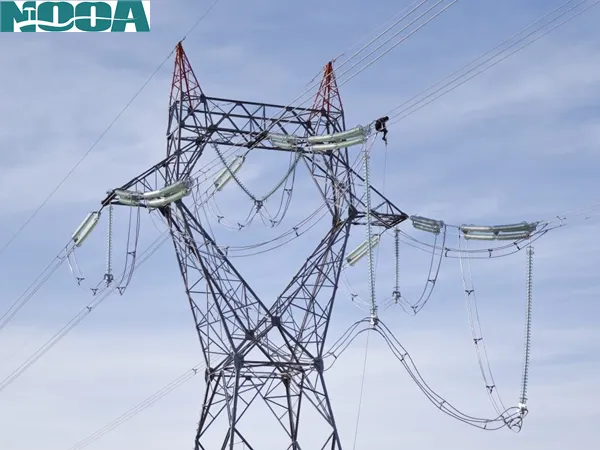

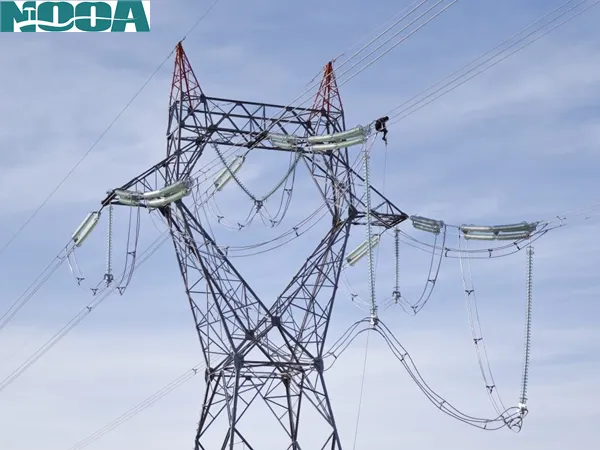

Toughened glass insulators are characterized by their visible zero-value self-explosion. When a glass unit self-explodes, the shattered glass disc falls away from the string, but the remaining glass fragments and metal fittings still maintain a relatively high residual mechanical strength—typically more than 80% of the ultimate breaking load.

This residual strength ensures that even if a single disc glass insulator in a string self-explodes, the entire string can still reliably carry the conductor tension without causing string breakage or conductor drop. Therefore, in practical operation, utilities usually do not perform complicated live-line mechanical tests on glass insulators; instead, they rely on routine patrol inspections to identify self-exploded units and schedule timely replacement.

Safety Design and Standard Requirements

In transmission line design and product selection, the following requirements are commonly applied:

-

The rated mechanical strength of the insulator must meet the maximum operating tension with an adequate safety factor.

-

The residual mechanical strength after mechanical damage must not fall below a specified percentage of the rated mechanical load or ultimate breaking load (as stipulated by relevant standards), ensuring sufficient load-bearing capacity of the insulator string even when one or a small number of units are damaged.

Significance in Design and Operation

For manufacturers:

Residual mechanical strength is a critical design and quality-control target for glass insulators. It directly depends on the tempering process, material formulation, and the coordination between high-strength cement and metal fittings. Superior manufacturing processes help achieve both high initial mechanical strength and excellent residual strength, ensuring long-term mechanical stability.

For utilities and operators:

Understanding the residual mechanical strength levels of glass insulators from different manufacturers and of different designs helps determine inspection intervals, assess operational risks, and develop replacement strategies after self-explosion events. This enables a balanced approach between system safety and maintenance cost control.

Testing the residual mechanical strength of glass insulators is usually carried out by intentionally creating a typical damage condition first, and then performing a mechanical load test to determine how much tensile force or bending moment the damaged insulator can still withstand and to compare the result with standard limit values.

How to test the residual mechanical strength of glass insulators

Test Purpose and Basic Principle

Purpose:

To verify that after damage such as partial disc breakage or self-explosion, the insulator can still reliably carry the service tension without causing string breakage or unit drop.

Principle:

Part of the glass is deliberately damaged in a specified manner to simulate in-service defects. The damaged insulator is then loaded on a dedicated mechanical testing machine, and its ultimate load capacity in the damaged condition is measured and compared with the rated mechanical strength or the percentage specified in relevant standards.

Typical Test Procedure (Tensile Residual Strength)

1. Specimen Preparation

-

Randomly select a specified number of glass insulators (e.g. disc-type suspension insulators) in accordance with the applicable standard.

-

Inspect the specimens to ensure intact appearance, sound metal fittings, and defect-free cemented joints; record the original rated mechanical load and ultimate breaking load.

2. Creation of Damage Condition

-

Use mechanical impact (such as steel-ball impact) or controlled directional striking to produce typical cracking or a “self-explosion” condition in the glass disc, ensuring that the fracture penetrates the glass body while the metal fittings remain securely connected.

-

The damage method shall comply with relevant national or company standards to ensure representative damage rather than complete pulverization.

3. Installation on the Test Machine

-

Mount the damaged insulator on a tensile testing machine according to the actual service load direction (axial tension for suspension insulators).

-

Ensure alignment of the loading axis with the insulator axis to avoid additional bending moments that could affect the test results.

4. Load Application

-

Apply the load continuously at the specified rate (e.g. uniformly up to the rated tensile load or at a standard-defined rate in kN/min).

-

Record the maximum load at which further failure or collapse of the damaged insulator occurs; this value is the residual breaking load.

5. Result Evaluation

-

Calculate the residual mechanical strength as a percentage of the original ultimate breaking load or rated mechanical strength.

-

If the residual strength is not less than the percentage required by the relevant standard (for example, not less than a specified proportion of the original breaking load), the residual mechanical strength of the batch or structural type is considered acceptable.

Other Forms of Residual Strength Tests

-

Bending / impact residual strength: For line-post or cross-arm glass insulators, local damage can be introduced first, followed by bending load or impact tests to determine the ultimate bending moment or impact resistance in the damaged condition.

-

Type tests and sampling inspections: Residual mechanical strength tests are generally conducted as part of type testing for new products or periodic sampling inspections. They are not required for every individual unit at delivery; instead, statistical methods are used to control overall product quality levels.