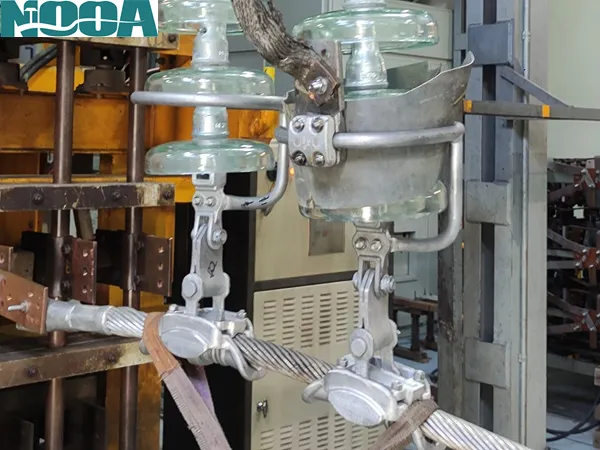

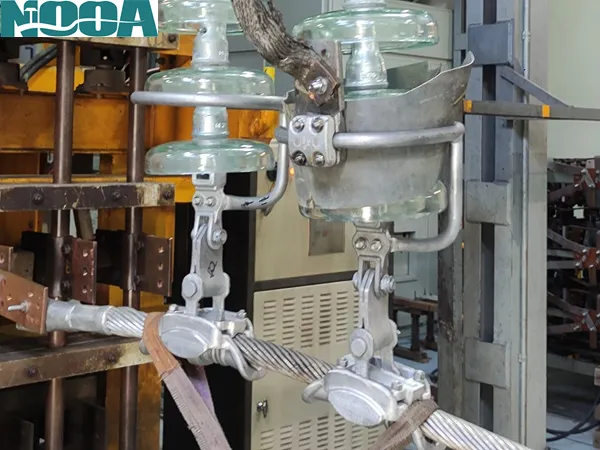

Suspension Fittings are a category of fittings used in overhead transmission lines for suspending and securing conductors (or optical cables). Typically located on the vertical upper section of towers, they connect the conductor to the

insulator string, undertaking the tasks of transferring vertical loads from the conductor, fixing the conductor, and working in conjunction with anti-vibration/damping systems to suppress wind-induced vibrations and galloping.

I. Definition and Core Functions of Suspension Fittings

Definition: Suspension Fittings (also known as Suspension Clamps or Hanging Fittings) are a set of fittings used to suspend conductors/optical cables from insulator strings, commonly used in the suspension sections of tangent (straight-line) towers.

Core Functions:

Transfer the weight and vertical loads of the conductor through the insulator string to the tower foundation, ensuring the stability of the line geometry and tension distribution.

Provide the initial fixing point for the conductor and, together with other fittings (such as vibration dampers, tension fittings), form a complete anti-galloping system, reducing the risk of fatigue and damage under complex loads like wind vibration and ice load.

II. Common Classifications and Differences

By Functional Distribution:

Suspension Clamps: Primarily used for suspending conductors from insulator strings, often used in suspension sections of tangent towers.

Tension Fittings: Used for fixing and tension transfer at the ends of conductors, commonly found at span terminals, responsible for setting the initial tension of the conductor.

Auxiliary Fittings: Such as vibration dampers, spiral vibration dampers, earth wire clamps, etc., used to reduce the transmission of wind vibration energy and local vibrations.

By Structures:

Different Structures like Tangent Suspension Clamps, Ship/Flat Type, Preformed Type, etc., differing in load-bearing capacity, applicable conductor cross-section, installation method, and compatibility with insulator strings.

By Connection Method:

Single-point vs. Multi-point support, Bolted connection vs. Drop/Wedge type, etc., affecting force transmission and fatigue behavior.

III. Common Elements of Structural Composition

Clamp Body: Carries the conductor and provides mechanical connection to the insulator string; common materials are steel or aluminum alloy, often with anti-corrosion coating.

Armor Rods / Conductor Guides: Used to guide the conductor along the correct path, reduce stress concentration, and improve installation and operational smoothness.

Connecting Pieces like U-bolts, Hooks: Enable mechanical connection to insulator strings and other fittings; require certain fatigue resistance.

Coupling Components for Vibration Dampers: Integrate vibration dampers, spiral dampers, etc., when needed, to enhance overall anti-galloping capability.

IV. Key Points for Selection and Design

Consideration Factors:

Conductor type (conventional conductor, OPGW, ADSS, etc.), its cross-section, mass distribution, and allowable tension.

Span length, tower type, mid-span height, wind/snow loads, geographical and climatic conditions.

Whether combination with vibration damping devices is necessary, and the target damping ratio and fatigue life requirements.

Design Principles:

Ensure the natural frequency of the suspension section avoids dominant wind vibration modes through modal and fatigue analysis, controlling stress concentration.

Selection should ensure the fatigue strength of connecting pieces meets long-term operational needs, avoiding failures due to improper trade-offs between excessive rigidity or excessive flexibility.

Maintainability and inspectability should be considered, ensuring components like fasteners and damping parts are easy to check and replace.

V. How Significant is the Vibration Damping Effect of Suspension Fittings on the Line?

The magnitude of the vibration damping effect of suspension fittings on the line depends on various factors, including the type of fitting, wind load, cable type, tower spacing, conductor configuration, vertical load and tension state, and surrounding environment (e.g., wind vibration, ice load, snow load). Generally, suspension fittings themselves primarily undertake two types of functions:

Distributing the weight and vertical loads of the conductor to the tower, reducing single-point stress concentration;

Working synergistically with anti-vibration/damping devices to suppress dynamic stresses caused by wind vibration and galloping, reducing the risk of fatigue damage. Below is a summary of key points regarding the damping effect, facilitating assessment in practical design and selection.

VI. Key Points and Influencing Factors

Anti-Vibration and Buffering Principle:

If the suspension fitting acts merely as a fixed connection, the damping effect mainly comes from associated anti-vibration devices (e.g., vibration dampers, spiral dampers) and the damping characteristics of the cable itself. Vibration dampers absorb vibration energy through a mass-damping mechanism, while spiral dampers disperse vibrations through local wrapping around the cable, thereby reducing peak wind vibration and vibration duration. Such combinations are particularly crucial in high wind speed, continuous wind vibration scenarios.

Structure and Material Comparison:

The material, cross-section, and connection method (single-point or multi-point support) of the suspension fitting directly affect local stiffness and damping transmission characteristics. Higher initial stiffness can sometimes help suppress certain high-frequency vibrations but may transfer stress concentration to local areas; appropriate flexible connections and damping components aid in energy dissipation for the overall system.

Coupling of Wind Vibration and Galloping:

Under wind force, conductors undergo subspan, transverse, and torsional vibrations. Properly configured suspension fittings, combined with damping devices, can effectively reduce the transmission of vibration energy from the conductor at the support points, decrease dynamic stress concentration in the span, and enhance the service life of the fittings and the safety margin of the tower.

Engineering Experience and Standards:

Line design for high voltage, extra-high voltage, and high-altitude areas often includes specific anti-galloping/damping design criteria for suspension fittings, including control of damping ratio and natural frequency, and checking of wind-induced vibration response. For large lines, standards and technical trends emphasize achieving comprehensive anti-galloping protection through equipment isolation and damping devices.

Application Scenario Examples:

Common damping measures in power optical cable fitting systems include: installing vibration dampers in suspension sections, applying spiral dampers around conductors, etc., to reduce the probability of fatigue damage induced by wind vibration. These measures typically form a complete damping scheme together with suspension fittings.

VII. Practical Suggestions for the Design and Selection of Suspension Fittings

Key Evaluation Points:

Wind vibration frequency and wind speed distribution: Determine the main vibration modes of the conductor and corresponding damping requirements through field wind statistics and wind tunnel/numerical simulation.

Cable and Material Characteristics: Different types of OPGW, ADSS, etc., have different damping properties, requiring selection of matching damping devices and fitting combinations.

Structural Geometry and Load Conditions: Tower height, span length, and geometric configuration in the tower span direction affect stress distribution and damping paths.

Common Practices:

Cooperate vibration dampers or spiral dampers in suspension sections to preliminarily dissipate wind vibration energy.

Increase the density and configuration of damping devices in sections requiring key protection (e.g., near towers, turning points) to reduce fatigue life loss.

Ensure the fatigue strength of connecting pieces, bolts, and other components of the suspension fittings meets long-term operational requirements, combined with seismic/anti-galloping design principles.

Through reasonable structural design of the suspension fittings themselves and synergistic use with anti-vibration and damping components, dynamic stresses caused by wind vibration and galloping can be significantly reduced, enhancing the fatigue life of the line and the protection level of the towers.