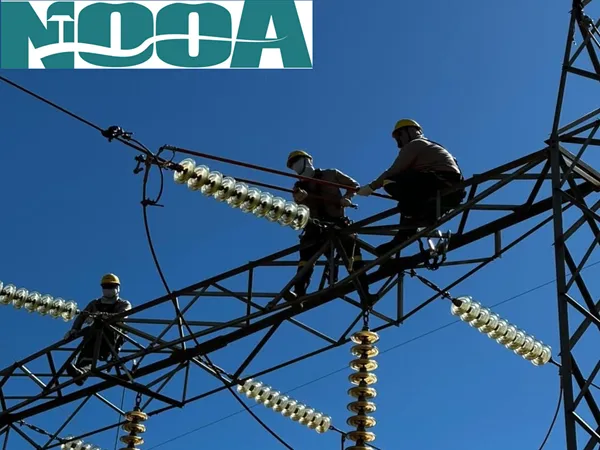

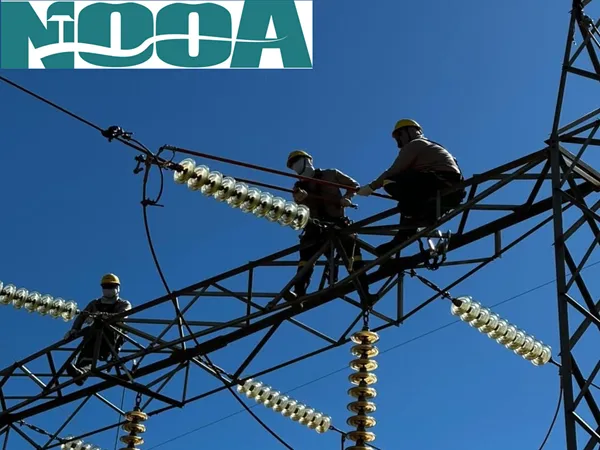

Disc-shaped insulators (commonly suspension or string insulators) are widely used in high-voltage transmission lines due to their durability and adaptability. Their design effectively combats environmental challenges like pollution, rain, ice, and UV exposure. Disc-shaped insulators are essential in high-voltage transmission systems, especially in outdoor environments. Their design and materials are optimized to withstand harsh environmental conditions, including rain, snow, dust, industrial pollution, and salt spray.

Designed for Harsh Conditions

These power insulators are engineered not just for electrical insulation but also for durability in real-world outdoor settings.

1. Long Creepage Distance

The disc shape increases the surface distance (creepage) along which a leakage current would have to travel. This is crucial in polluted or wet environments, where the surface can become conductive.

2. Water Shedding Surface

The curved, umbrella-like profile of disc insulators allows rainwater to run off easily, minimizing the formation of conductive water films that could cause flashovers.

3. Pollution-Resistant Material

Glass insulators feature a smooth, hydrophilic surface that resists dirt accumulation and washes clean during rainfall. This self-cleaning effect helps maintain insulation performance in polluted areas.

Weather and Pollution Performance in Practice

In different environmental zones—from deserts to coastal regions—disc insulators maintain stability due to their strong physical and chemical properties.

UV and Temperature Resistance

Glass is naturally resistant to ultraviolet radiation and extreme temperature fluctuations, ensuring long-term performance without degradation.

Ice and Snow Performance

In freezing climates, the disc shape helps minimize ice accumulation, and any buildup is less likely to bridge the insulation path due to the rounded profile.

Easy Inspection and Maintenance

The transparency of glass makes it easy to spot cracks or damage during inspections, allowing for proactive maintenance in tough environments.

Maintenance & Failure Prevention

Regular Inspections

-

Visual checks for cracks, contamination, or flashover marks.

-

Infrared thermography detects hotspots from leakage currents.

Mitigation Strategies

Q&A Section

Q1: How do disc-shaped insulators prevent flashovers during rain?

A1: Their shed-like design allows water to flow off quickly, preventing continuous wet films that could conduct electricity.

Q2: What makes glass insulators good for polluted environments?

A2: Glass has a smooth, self-cleaning surface that reduces dirt buildup and maintains electrical integrity.

Q3: Can disc insulators withstand coastal or industrial pollution?

A3: Yes, their long creepage distance and resistance to corrosion make them suitable for high-pollution zones.

Q4: Do weather changes affect the performance of disc insulators?

A4: No, glass insulators are stable under extreme UV, heat, cold, and moisture, maintaining their dielectric strength.