110kV suspension fittings are essential components in overhead power transmission lines. Their primary role is to support conductors, reduce aeolian vibration, and ensure long-term mechanical and electrical reliability. This article explains how suspension clamps, armor rods, and other hardware work together to protect 110kV conductors, extend service life, and maintain line stability even under strong wind and harsh environmental conditions. As a trusted manufacturer, Nooa Electric provides globally compliant 110kV suspension fittings engineered for quality, safety, and long-term performance.

What Are 110kV Suspension Fittings?

Suspension fittings support the conductor on towers, allow angular movement, and prevent mechanical stress concentration.

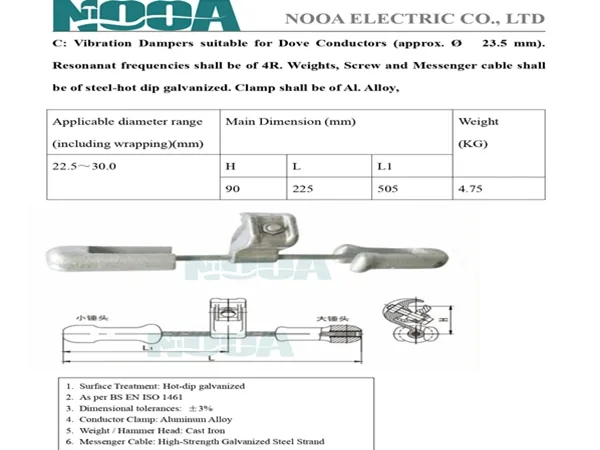

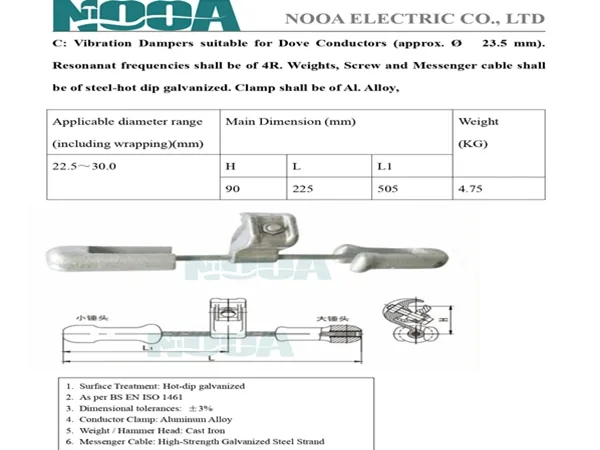

110kV suspension fittings—also called 110kV suspension hardware, suspension clamps, or hanger fittings—are used to hang conductors or OPGW cables on transmission towers. Their structure typically includes suspension clamps, yoke plates, shackles, clevises, and protective armor rods.

These fittings are designed to distribute mechanical load evenly whileenabling the conductor to swing smoothly. This prevents bending, fatigue, and stress that can shorten the conductor’s lifespan.

How Suspension Fittings Reduce Aeolian Vibration

They reduce wind-induced vibration by absorbing energy, increasing damping, and preventing conductor fatigue.

Aeolian vibration is a major threat to overhead lines, especially in 110kV systems where long spans and strong winds are common. The suspension clamp and armor rod combination works as a vibration mitigation system:

-

Vibration energy is dissipated through the clamp body and elastomer inserts.

-

Armor rods increase conductor stiffness, distributing stress across a larger area.

-

High-strength alloy materials resist cyclic mechanical fatigue.

-

Optimized clamp grooves minimize abrasion and stress concentration.

By addressing both micro-vibration (high frequency, low amplitude) and subspan oscillation, Nooa Electric’s 110kV suspension fittings help maintain conductor integrity for decades.

Protection Mechanisms Against Conductor Damage

Suspension fittings protect conductors from wear, bending, abrasion, and electrical or mechanical failure.

110kV suspension hardware provides multi-layer protection through:

-

Uniform load transfer to prevent point pressure on the conductor.

-

Anti-slip clamp design ensuring firm but non-damaging grip.

-

Corrosion-resistant galvanized steel and aluminum alloy for long service life.

-

Electrical insulation support when used with insulator strings.

-

Armor rods shielding the conductor from wind-induced wear.

These design features prevent common issues such as strand breakage, bending strain, and clamp abrasion.

Role of Armor Rods in Conductor Protection

Armor rods distribute mechanical stress and protect conductors against abrasion and vibration.

Armor rods—an essential part of 110kV suspension fittings—are helically formed rods wrapped around the conductor. They offer:

-

Stress distribution over a larger area

-

Enhanced conductor bending radius

-

Additional vibration damping

-

Physical protection against clamp wear and flashover

In coastal, desert, or high-wind regions, armor rods significantly improve conductor reliability and reduce maintenance frequency.

Why High-Quality Materials Matter for 110kV Lines

Stronger materials ensure load capacity, corrosion resistance, and overall system safety.

Nooa Electric uses hot-dip galvanized steel, forged steel, and corrosion-resistant aluminum alloy, ensuring:

-

High mechanical strength for heavy conductors

-

Long-term protection against rust and humidity

-

Stable performance under extreme weather

-

Better conductor flexibility and vibration control

Material quality is essential for maintaining safety in 110kV transmission infrastructure.

Applications of Nooa Electric 110kV Suspension Fittings

Suitable for all 110kV overhead lines, including long-span, coastal, and high-wind regions.

Typical applications include:

-

110kV overhead transmission lines

-

Long-span tower sections

-

Mountainous or coastal environments

-

OPGW/ground wire suspension systems

-

Areas with heavy wind or ice load

Nooa Electric designs fittings that comply with IEC, IEEE, and GB standards, making them reliable for global power utilities and EPC contractors.

FAQ About 110kV Suspension Fittings

1. What is the main function of 110kV suspension fittings?

They support the conductor on transmission towers, reduce vibration, and protect against mechanical damage.

2. Do 110kV suspension clamps need armor rods?

Yes, armor rods are recommended to avoid conductor wear, distribute stress, and improve vibration damping.

3. How do suspension fittings prevent conductor fatigue?

By allowing controlled movement, absorbing vibration energy, and preventing concentrated bending stress.

4. What standards do 110kV fittings follow?

Typically IEC and GB/T standards, depending on the project requirements.

5. Why choose Nooa Electric?

Nooa Electric provides high-quality materials, strict testing, and global project experience, ensuring long service life and safety for transmission lines.

Custom glass insulators & related hardware fittings with IEC type test, fast delivery & tender qualification.

Experienced China factory exporting to Europe, Africa, Asia, Middle East & South America.

Familiar with your country's powerline design & customs policy. OEM design & strict testing ensured.

Professional glass insulator hardware fittings supplier with full test reports & bid certificates.