Transmission lines are the backbone of electrical power distribution, transporting high-voltage electricity over vast distances from power generation plants to substations and ultimately to consumers. Ensuring the safe and efficient delivery of this power is crucial, and one of the key components that facilitate this process is the insulator. Insulators are vital to the structural integrity and functionality of transmission lines, preventing power outages, electrical faults, and other dangerous conditions.

The Role of Insulators in Transmission Lines

In high-voltage power transmission systems, it is vital that electrical current flows safely through conductors—usually made of aluminum or copper—without inadvertently contacting surrounding structures like towers, poles, or the ground. This is precisely where insulators become essential: they provide electrical separation between live wires and grounded components such as transmission towers, cross-arms, and utility poles, helping to ensure the current remains confined to its intended path.

Insulators play a dual role in transmission systems by providing electrical isolation and mechanical support. They securely suspend high-voltage conductors in place while preventing electrical current from leaking to adjacent conductive structures. Without reliable insulators, transmission lines would face serious risks such as short circuits, electrical fires, and hazardous electric shocks, posing threats to both infrastructure integrity and public safety.

Materials Used in Insulators

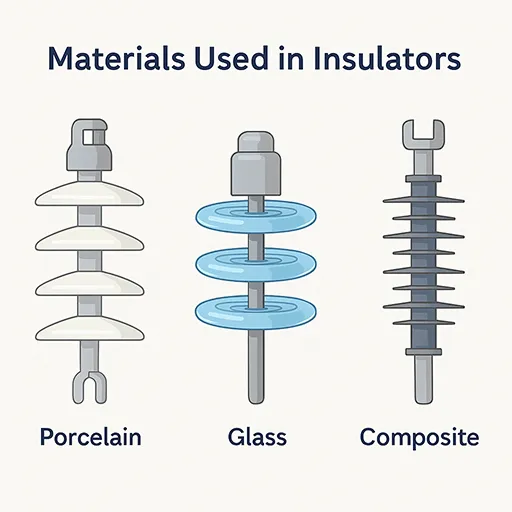

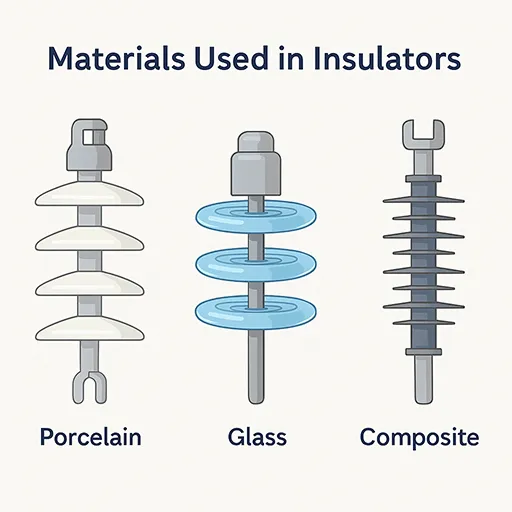

Insulators in transmission lines are made from materials that offer excellent electrical resistance and robust mechanical strength—qualities necessary to prevent current leakage and endure harsh environmental conditions.

The most commonly used insulator materials fall into three main categories: porcelain, toughened glass, and composite polymers.

Porcelain has traditionally been the go-to material for insulators, valued for its strong insulating capabilities and robust mechanical performance. Produced by firing refined clay at high temperatures and applying a glazed finish, porcelain insulators effectively resist moisture infiltration. The smooth glaze not only enhances weather resistance but also helps prevent surface leakage caused by contaminants or humidity.

Glass insulators have gained widespread use due to their high dielectric strength and the distinct advantage of visible damage detection—cracks or chips are easy to identify. Although glass is more brittle than porcelain, it absorbs less moisture and offers superior resistance to surface pollution. Its naturally smooth, hydrophilic surface allows rain to wash away dust and grime, making it effectively self-cleaning.

To further enhance glass insulators, RTV-coated often applied. RTV-coated glass insulators combine the inherent strength of toughened glass with added surface protection. This coating reduces the accumulation of contaminants and boosts performance in harsh environments, including coastal areas and regions with acid rain, heavy fog, or industrial pollution. Unlike traditional materials, RTV-coated insulators retain durability and electrical performance even under prolonged environmental stress.

Composite insulators, made from advanced materials such as silicone rubber and fiberglass-reinforced polymers, offer a lightweight and flexible alternative. These modern insulators are highly resistant to breakage, UV degradation, and surface contamination, making them ideal for installations requiring reduced weight, corrosion resistance, or mechanical flexibility.

Application and Installation

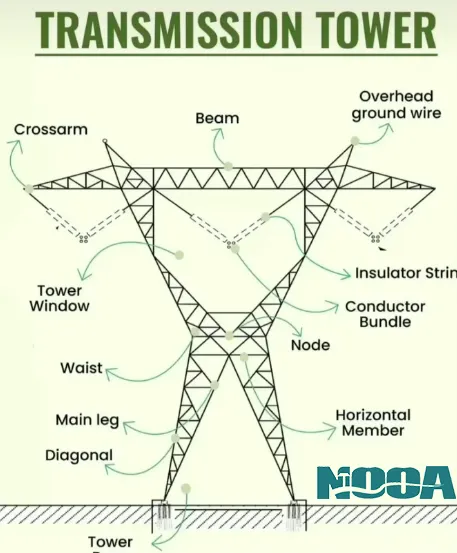

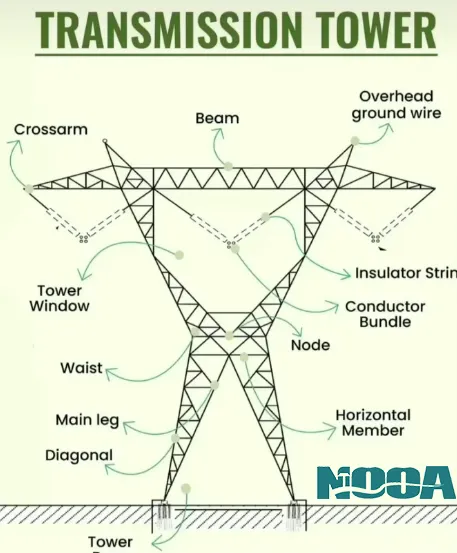

The installation of insulators in transmission lines is a precisely engineered process aimed at maximizing both safety and performance. A variety of factors are taken into account, including voltage ratings, mechanical loads, environmental conditions, and the overall design of the transmission system. Insulators are typically installed on the cross-arms of towers or directly onto poles, selected according to their ability to withstand the specific electrical and environmental demands of the site.

For high-voltage applications, insulators are often arranged in series, forming strings long enough to provide sufficient electrical isolation. As the voltage increases, so does the number of insulator units needed per string. For instance, a 400 kV transmission line may require 16 or more suspension discs in each insulator string.

Engineers install specialized insulators in regions with heavy pollution or coastal exposure, choosing designs like anti-pollution types or those with extended creepage distances—the surface length over which leakage current may travel. These designs help to prevent flashovers caused by contaminants like salt or industrial deposits, maintaining safe and reliable operation even in the most demanding environments.

Why Are Glass Insulators Preferred in High-Voltage Transmission?

Glass insulators are favored due to their high mechanical strength, excellent resistance to weathering, and lower maintenance requirements. Their transparency allows for visual detection of damage, making them safer and more reliable in critical transmission infrastructure.

Conclusion

As modern power networks evolve, glass insulators continue to stand out for their reliability, durability, and safety. By choosing the right type of glass insulator—whether standard or RTV-coated—utilities can ensure long-term performance even in the most demanding conditions.